How Spam is Made

I have seen a lot of Spam here lately. People use one-liners for points or post nonsense or affiliate links without context. But what is Spam, and how is it made? Funny you should ask.

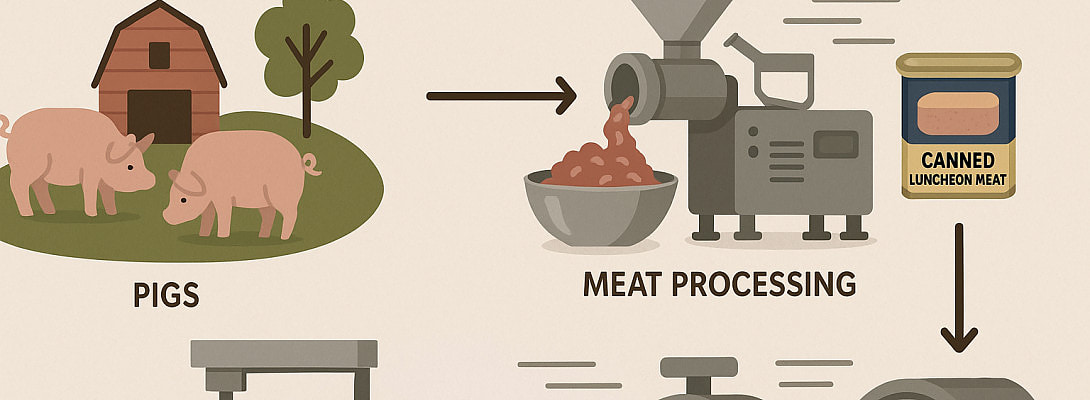

How SPAM Is Made: From Pig to Pantry

Ever wondered how that iconic blue-and-yellow can ends up on your shelf? The process is simpler than you might think, yet every step demands tight control to keep the taste and texture consistent. Let’s walk through it from farm to finished product, so the next time you slice a block for breakfast, you’ll know exactly what went into it.

The journey starts on the hog farm. Producers select lean pork shoulder and ham cuts because they bring the right balance of protein and fat. USDA inspectors check the animals and the meat for health and quality. Once approved, chilled pork travels to the processing plant, where the real work begins.

Inside the plant, butchers trim the cuts and grind them to a coarse mince. Salt goes in early; it binds the meat proteins, holds moisture, and extends shelf life. Sugar, potato starch, and a touch of sodium nitrite follow. Sugar rounds out the flavor, starch keeps the mixture firm, and nitrite protects color and blocks harmful bacteria. Everything moves into a chilled mixer that whips the mince into a smooth pink emulsion—the distinctive SPAM texture you see when you pop the lid.

Next comes portioning. A piston-style filler shoots the emulsion into rectangular cans at high speed while pulling a light vacuum. Removing air prevents spoilage and stops the meat from oxidizing. Each can rolls under a seamer that crimps an aluminum lid to the steel body, creating an airtight double seam. Every lid gets a stamped code that tracks the batch and date.

Sealed cans enter giant pressure cookers called retorts. Steam raises the internal temperature to about 240°F (115 °C) for roughly three hours. This high-heat step kills microbes, sets the protein for that familiar loaf-like slice, and drives the final vacuum as the contents cool. Technicians monitor time, temperature, and pressure on digital controls; any deviation triggers an alarm and a hold order for the entire lot.

Once cooked, cans ride through cold showers that drop their core temperature below 90°F in minutes. Labeling machines wrap each can, packers stack them into cases, and quality staff pull random samples for sensory tests and shelf-life checks. If everything passes—that means good seal integrity, correct weight, and the signature savory aroma—the cases head to warehouses and, soon after, to stores worldwide.

From pig to pantry, the full run takes less than two days, yet the product can stay safe and tasty for years at room temperature. That shelf life, along with its salty-sweet flavor, explains why SPAM feeds campers, hurricane prep kits, and midnight snackers alike. The next time you crack a can, picture the farm, the stainless-steel mixers, and the roaring retorts behind every bite. Feeling hungry yet?

Join FREE & Launch Your Business!

Exclusive Bonus - Offer Ends at Midnight Today

00

Hours

:

00

Minutes

:

00

Seconds

2,000 AI Credits Worth $10 USD

Build a Logo + Website That Attracts Customers

400 Credits

Discover Hot Niches with AI Market Research

100 Credits

Create SEO Content That Ranks & Converts

800 Credits

Find Affiliate Offers Up to $500/Sale

10 Credits

Access a Community of 2.9M+ Members

Recent Comments

23

This post is chef's kiss—equal parts educational and clever 😄

I came in expecting a rant about digital spam (and maybe a plea for better internet etiquette), but got a full behind-the-scenes tour of SPAM, the meat! The processing detail—from the pork shoulder to pressure cookers—was surprisingly fascinating. I had no idea the shelf-stable magic of SPAM came together in just two days.

Also, I love the double meaning here. Just like real SPAM has its recipe, digital spam often follows a predictable (and unfortunately lazy) formula—no flavor, no context, just filler.

Here’s to keeping our communities meaty (with value), not spammy.

And if anyone needs a break from the nonsense and wants a dose of viral goodness.

Stay savory,

@virginmask

Hey Michael,

Thank you for the interesting story. I had no idea.... a long of work to get to the finished product I think. Thank God for automation.

In 2017 when 2 major hurricanes struck Grand Turk, Turk & Caicos, the power was out for months. I remember cooking rice on aluminum foil on the BBQ and opening up a can of SPAM. That was the first time I ate SPAM. Not much was readily available at the grocery stores. The taste was ok... and I certainly thanked God that we had lots of cans at the stores.

Regards,

Monica

The emergency meat. This is not the first time I have heard a story about how it helped someone survive after a natural disaster.

Thanks for sharing.

Michael

See more comments

Join FREE & Launch Your Business!

Exclusive Bonus - Offer Ends at Midnight Today

00

Hours

:

00

Minutes

:

00

Seconds

2,000 AI Credits Worth $10 USD

Build a Logo + Website That Attracts Customers

400 Credits

Discover Hot Niches with AI Market Research

100 Credits

Create SEO Content That Ranks & Converts

800 Credits

Find Affiliate Offers Up to $500/Sale

10 Credits

Access a Community of 2.9M+ Members

I Love me some spam. There is nothing any better than Spam and Eggs! Fry you up some Spam and make sandwiches. I remember my Grandma making those for us before we would go hunting or fishing. I just never knew the process of how they made it. Thanks for the post.